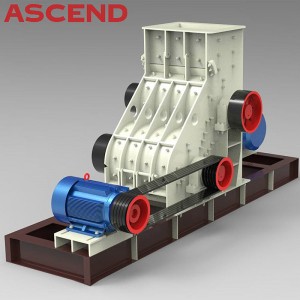

Wet Coal Material Double Stage Hammer Crusher

Double rotor hammer crusher mill is suitable for crushing wet or sticky material, like calcite, limestone, coal slag,furnace slag,ore slag in the brick plant, construction wastes,shale,coal gangue. Because not like the common hammer crusher, double rotor hammer crusher does not have the grate screen under the bottom discharge mouth, so it avoids the problem of choking and stuck. In fact, double rotor Stage hammer Crusher is the same as two Hammer Crushers combining together reasonably. Two rotors are applied at the same time in this machine.The double rotor hammer crusher major spare parts is the hammer, which is made of manganese alloy material, can last way more longer working time than the common steel alloy.

Working Principle

When it works, the twin-stage crusher’s two rotors revolve at the same time at high speed driven by the double electric motors.

Materials in the crushing cavity are immediately crushed by the lower rotor’s hammerhead with high-speed rotation after first being crushed by the high-level rotor.

Materials are completely impacted with each other and crushed into the coal cinder powder with the discharging size less than 3mm.

Two-Stage Hammer Crusher Technical Parameter

|

Specifition |

Capacity |

Motor Power |

|

ZPCΦ600×600 |

20-30 |

22kw+22kw |

|

ZPCΦ800×600 |

35-55 |

45kw+55kw |

|

ZPCΦ1000×800 |

60-90 |

55kw+75kw |

|

ZPCΦ1200×1000 |

80-120 |

90kw+110kw |

|

ZPCΦ1400×1200 |

100-140 |

132kw+160kw |

|

ZPCΦ1600×1400 |

120-180 |

160kw+200kw |

Double Rotor Hammer Crusher Delivery

The double rotor hammer crushers are packed in wooden box or container for exporting. Before delivery, we will pack every part well, and do the water and rust proof handling to ensure you can receive a sound and brand new machine.