OEM manufacturer Planetary Ball Mill Machine - Gravel Aggregates Vibrating Screen Machine – Ascend

OEM manufacturer Planetary Ball Mill Machine - Gravel Aggregates Vibrating Screen Machine – Ascend Detail:

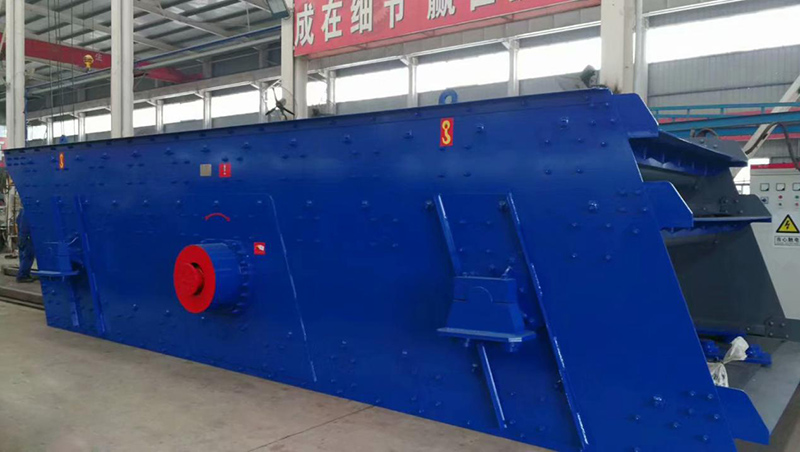

The circular vibrating screen is a high-efficiency and new-type vibrating screen featured by circular vibration and multi-layers This type of vibrating screen is specially designed for screening material stone of a quarry, and widely used for product classification in mining, building materials, transportation, energy, chemical products industries. So, it’s a kind of ideal equipment used in the crushing and screening unit. If the screen with small boring diameter is installed, the wet and sticky material can not be screened unless the water spraying method is used.

Working Principle

The circular vibrating screen is mainly composed of screen box, vibration exciter, suspension (or support) device and motor, etc. The motor drives the main shaft of the exciter to rotate through the V-belt, and the screen box vibrates due to the centrifugal inertia force of the unbalanced weight on the exciter. Different amplitudes can be obtained by changing the eccentric axis of the exciter.

Product Advantages

1.Adopt block eccentric as exciting force, and it is very high.

2. Adopt high strength bolts between beam and screening box, simple structure and easy maintenance.

3. Adopt tire coupler and it is connected flexibility and the operation is stable.

4. Adopt small amplitude, high frequency, and also big inclination, which makes that the machine has high efficiency, big capacity, long lifetime, low power and noise.

Specification

|

Model |

Screen |

Screen |

Mesh |

Feeding |

Capacity |

Vibrating |

Double |

Power |

Dimension |

Weight |

Screen |

Screen |

| YK1237 | 1 | 4.4 | 2-50 | 200 | 25-160 | 970 | 8 | 11 | 3857×2386×2419 | 4.8 | 15-20 | 1200×3700 |

| 2YK1237 | 2 | 4.4 | 2-50 | 200 | 25-160 | 970 | 8 | 11 | 3857×2386×2419 | 4.9 | 15-20 | 1200×3700 |

| 3YK1237 | 3 | 4.4 | 2-50 | 400 | 30-180 | 970 | 8 | 11 | 4057×2386×2920 | 5.2 | 15-20 | 1200×3700 |

| 4YK1237 | 4 | 4.4 | 2-50 | 400 | 30-180 | 970 | 8 | 11 | 4257×2386×2920 | 5.3 | 15-20 | 1200×3700 |

| YK1548 | 1 | 7.2 | 2-50 | 200 | 45-250 | 970 | 8 | 15 | 4904×2713×2854 | 5.9 | 15-20 | 1500×4800 |

| 2YK1548 | 2 | 7.2 | 2-50 | 200 | 45-250 | 970 | 8 | 15 | 4904×2713×2854 | 6.3 | 15-20 | 1500×4800 |

| 3YK1548 | 3 | 7.2 | 2-50 | 400 | 45-280 | 9708 | 8 | 15 | 5104×2713×3106 | 6.5 | 15-20 | 1500×4800 |

| 4YK1548 | 4 | 7.2 | 2-50 | 400 | 45-280 | 970 | 8 | 18.5 | 5304×2713×3356 | 6.6 | 15-20 | 1500×4800 |

| YK1848 | 1 | 8.6 | 2-50 | 200 | 55-330 | 970 | 8 | 15 | 4904×3041×2854 | 6.2 | 15-20 | 1800×4800 |

| 2YK1848 | 2 | 8.6 | 2-50 | 200 | 55-330 | 970 | 8 | 15 | 4904×3041×2854 | 6.9 | 15-20 | 1800×4800 |

| 3YK1848 | 3 | 8.6 | 2-50 | 400 | 55-350 | 970 | 8 | 22 | 5104×3041×3106 | 7.2 | 15-20 | 1800×4800 |

| 4YK1848 | 4 | 8.6 | 2-50 | 400 | 55-350 | 970 | 8 | 22 | 5304×3041×3356 | 7.5 | 15-20 | 1800×4800 |

| YK1860 | 1 | 10.8 | 2-50 | 200 | 65-350 | 970 | 8 | 22 | 6166×3041×2854 | 6.4 | 15-20 | 1800×6000 |

| 2YK1860 | 2 | 10.8 | 2-50 | 200 | 65-350 | 970 | 8 | 22 | 6166×3041×2854 | 7.1 | 15-20 | 1800×6000 |

| 3YK1860 | 3 | 10.8 | 2-50 | 400 | 65-380 | 970 | 8 | 22 | 6366×3041×3106 | 7.4 | 15-20 | 1800×6000 |

| 4YK1860 | 4 | 10.8 | 2-50 | 400 | 65-380 | 970 | 8 | 30 | 6566×3041×3356 | 7.7 | 15-20 | 1800×6000 |

| YK2160 | 1 | 12.6 | 2-50 | 200 | 80-720 | 970 | 8 | 30 | 6166×3444×2854 | 9.9 | 15-20 | 2100×6000 |

| 2YK2160 | 2 | 12.6 | 2-50 | 200 | 80-720 | 970 | 8 | 30 | 6366×3444×3106 | 11.2 | 15-20 | 2100×6000 |

| 3YK2160 | 3 | 12.6 | 2-50 | 400 | 90-750 | 970 | 8 | 37 | 6566×3444×3356 | 12.4 | 15-20 | 2100×6000 |

| 4YK2160 | 4 | 12.6 | 2-50 | 4050 | 90-750 | 970 | 8 | 45 | 6566×3444×3356 | 15.1 | 15-20 | 2100×6000 |

| YK2460 | 1 | 14.4 | 2-50 | 200 | 150-810 | 970 | 8 | 30 | 6166×3916×3839 | 12.2 | 15-20 | 2400×6000 |

| 2YK2460 | 2 | 14.4 | 2-50 | 200 | 150-810 | 970 | 8 | 30 | 6166×3916×3839 | 13.5 | 15-20 | 2400×6000 |

| 3YK2460 | 3 | 14.4 | 2-50 | 400 | 180-900 | 970 | 8 | 37 | 6366×3916×4139 | 13.6 | 15-20 | 2400×6000 |

| 4YK2460 | 4 | 14.4 | 2-50 | 400 | 180-900 | 970 | 8 | 45 | 6566×3916×4439 | 14.4 | 15-20 | 2400×6000 |

Product detail pictures:

Related Product Guide:

We goal to see good quality disfigurement within the manufacturing and provide the most effective support to domestic and overseas shoppers wholeheartedly for OEM manufacturer Planetary Ball Mill Machine - Gravel Aggregates Vibrating Screen Machine – Ascend , The product will supply to all over the world, such as: Sudan, Belize, Ecuador, Our mission is to deliver consistently superior value to our customers and their clients. This commitment permeates everything we do, driving us to continuously develop and improve our products and the processes to fulfill your needs.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.