A South American customer is planning to build a small stone production line. After the joint efforts of our business and engineering team, we successfully help the customer build a 30-ton per hour river stone crushing and screening production plant.

Customer Requirements:

Raw material: pebble stone

Input Material size: 350mm

Final Products: 0-4mm, 4-13mm, 13-19mm, 19-25mm four kinds of coarse sand and gravels.

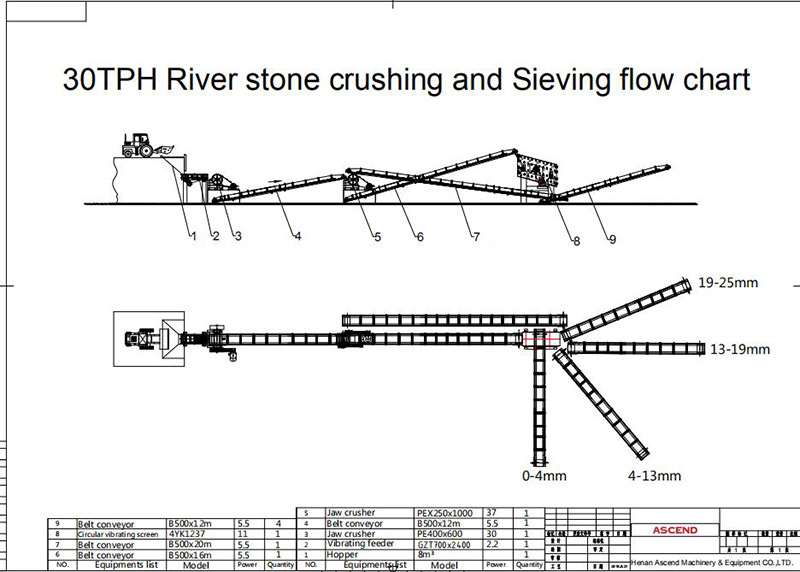

Production Process: This production plant adopts coarse crushing, medium crushing and screening processes to produce four types of sand and gravel products. The specific process is to use truck to put the raw material into the hopper, and then raw stone is conveyed into the coarse crushed jaw crusher through the vibrating feeder. After being crushed, it is transported to the medium fine crushing PEX series jaw crusher by the belt conveyor, and then the crushed stone is conveyed to the vibrating screen through the belt conveyor. The qualified output sizes are screened out and conveyed by the conveyor. The over sized aggregates are returned back to the fine jaw crusher for recrushing. This process forms into a close circuit and work continuously.

The main line of this production line is:

1 set of PE400×600 jaw crusher;

2 sets of PEX250×1000 jaw crusher;

1 set of 3YK1237 circular vibrating screen;

Auxiliary equipment: Vibrating feeder, belt conveyors form a production line.

The detailed flow chart is as follows:

Conclusion:

The design of this project is simple and the selected equipment is mature and stable. After 20 working days of production in the Chinese factory, it is delivered on time. The post-installation and commissioning work progressed smoothly. It was successfully put into operation at the end of November, and the sand and gravel products produced satisfies the needs of the local small-scale construction market. The production and sales of the factory are booming.

Post time: 21-06-21