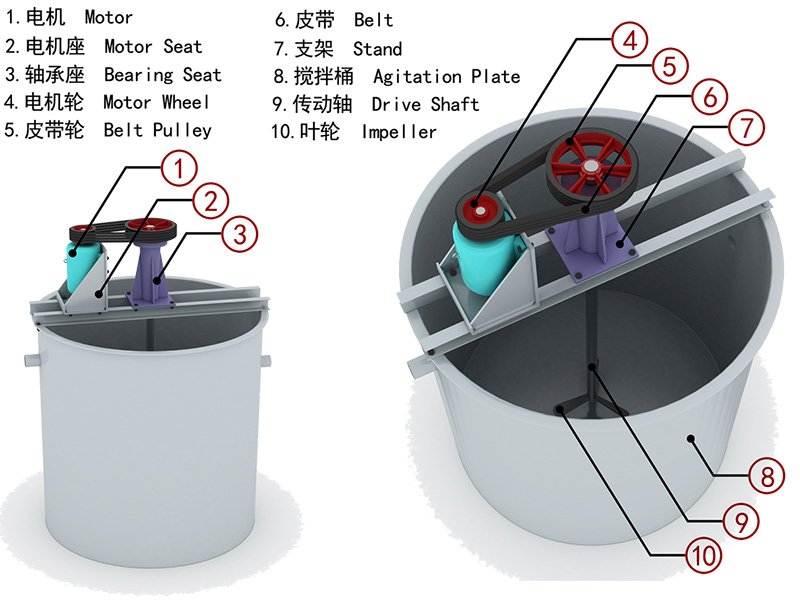

Mining Ore Mixer Tank Machine

Mineral agitation barrel is the necessary equipment which mixes the drug and pulp to add the reaction time of chemical agent and strengthen drug reaction quality. It is suitable for ore dressing and all kinds of mixing operations in chemical industry. Mineral agitation barrel is suitable for all kinds of metal ore, which is mainly used for mixing before flotation. It can make the pharmacy and slurry fully mixed, which can also be used for stirring other non-metallic minerals. Mixer is suitable for the material with not more than 30% concentration (by weight) and fixed components size less than 1mm. Due to the properties of mixer, it also can be called stirring tank, mineral mixing barrel and agitation vat.

Working Principle

The mixing bucket is composed of motor, impeller, stator, bearing and other components. The mixing operation is carried out by using the flat bottom drum radiation circulation spiral impeller mechanical mixing method. When the mixing tank is working, the motor pulls the triangle belt drive device to drive the impeller to rotate. Under the constant speed mixing of the impeller, the slurry and the agent can fully mix with each other, increase the reaction time of the agent to the slurry, strengthen the reaction quality of the drug, so that the material can be fully stirred and mixed, and make necessary preparation for the next stage of the flotation machine production.

Specifications

|

Internal size of trough |

Effective volume |

Stirrer |

Motor |

Overall dimension |

Weight |

||||

|

Diameter |

Height |

Diameter |

Rotation speed |

Model |

Power |

Total height |

Max length |

||

| 1000 | 1000 | 0.58 | 240 | 530 | Y100L-6 | 1.5 | 1665 | 1300 | 685 |

| 1500 | 1500 | 2.2 | 400 | 320 | Y132S-6 | 3 | 2386 | 1600 | 861 |

| 2000 | 2000 | 5.6 | 550 | 230 | Y132ml-6 | 4 | 3046 | 2381 | 1240 |

| 2500 | 2500 | 11.2 | 625 | 230 | Y160M-6 | 7.5 | 3546 | 2881 | 3462 |

| 3000 | 3000 | 19.1 | 700 | 210 | Y225S-8 | 18.5 | 4325 | 3266 | 4296 |