Limestone Rock Horizontal Shaft Sand Making Crusher

High efficiency fine crusher, also called sand making crusher, is widely used to produce sand and fine size gravel. It can be used to crush hard or medium hard stone, like granite, basalt, quartz, limestone etc. Its output size is usually less than 5mm, which is very suitable for block making and sand production.

Technical Specifications

|

Model |

Rotation speed |

Quantity of |

Diameter |

Length |

Input size |

Output size |

Capacity |

Motor Power |

Dimension |

| 800×400 | 860 | 12 | 800 | 400 | ≤120 | 5 | 30-40 | 45 | 2.1x1.4x1.7 |

| 800×600 | 860 | 18 | 800 | 600 | ≤180 | 5 | 40-50 | 55 | 2.1x1.62x1.7 |

| 800×800 | 860 | 24 | 800 | 800 | ≤180 | 5 | 50-70 | 55 | 2.1x1.84x1.96 |

| 1010×1010 | 720 | 30 | 1010 | 1010 | ≤180 | 5 | 60-75 | 75 | 2.1x1.84x1.96 |

| 1200×1000 | 590 | 30 | 1200 | 1000 | ≤180 | 5 | 100-110 | 110 | 2.45x1.6x1.96 |

| 1200×1200 | 590 | 24 | 1200 | 1200 | ≤180 | 5 | 120-150 | 132 | 3.0x2.16x2.5 |

| 1400×1400 | 540 | 24 | 1400 | 1400 | ≤180 | 5 | 160-200 | 160 | 3.0x2.36x2.55 |

| 1600×1600 | 460 | 24 | 1600 | 1600 | ≤190 | 5 | 180-250 | 250 | 3.0x2.76x2.5 |

| 1800×1800 | 420 | 24 | 1800 | 1800 | ≤190 | 5 | 220-290 | 315 | 3.0x3.26x3.15 |

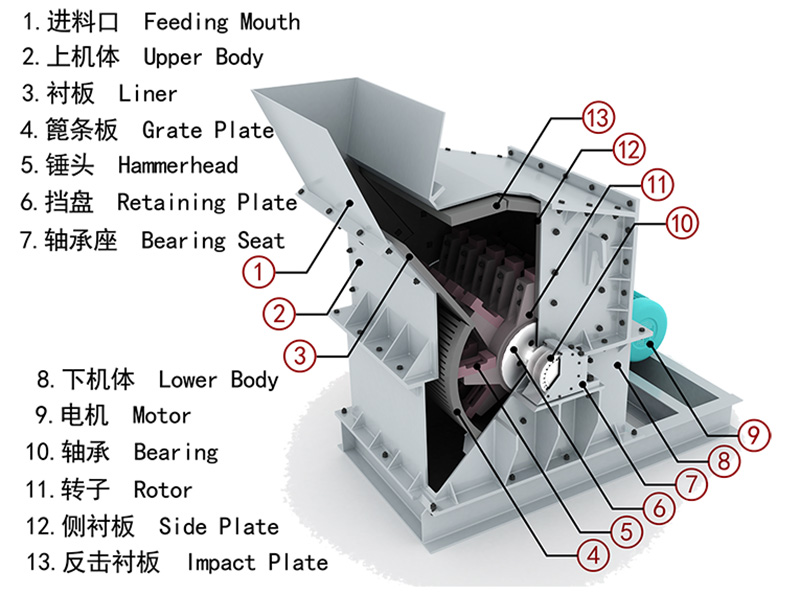

Working Principle Of Hsi Sand Fine Crusher

The high efficient fine crusher adopts the principle of "stone striking stone", which makes the materials collide and crush by themselves. The finished product has a good grain shape, which reduces the wear of machinery and equipment, and improves the output of finished products. It fully meets the national construction sand and gravel standards and is widely used in highway, building concrete mixing, and other fields. The key wear-resistant parts are made of high-iron and high-iron wear-resistant materials with long service life. Compared with the traditional fine crusher, the hydraulic device and the thin oil lubrication station are added, and the unique feeding system makes it have the characteristics of high energy and low consumption, excellent grain shape, easy maintenance, automatic maintenance, safety and reliability, and multiple uses in one machine.