ASCEND portable Mobile diesel engine jaw crusher for granite marble hard stones

Products video

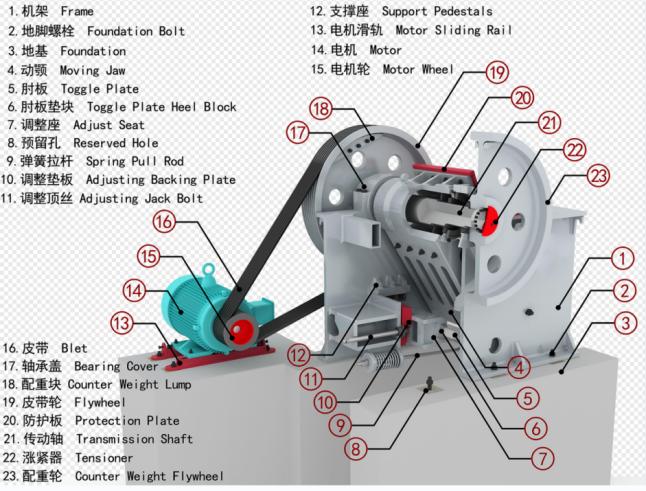

Working principle

The jaw crusher is primary crusher, the motor drives the pulley and flywheel to move the eccentric shaft, SO as to drive the moving jaw plate to move up, down, left and right.From the feeding mouth, the materials enter, they are crushed by the movable jaw plate and fixed jaw plate, and finally they are broken into the output size what they need. If the jaw crusher is small, it can be also used to the secondary crusher.

Specification

|

Model |

Max.feeding size(mm) |

Output size(mm) |

Capacity(t/h) |

Motor power(kw) |

Weight(kg) |

|

PE250X400 |

210 |

20-60 |

5-20 |

15 |

2800 |

|

PE400X600 |

340 |

40-100 |

16-60 |

30 |

7000 |

|

PE500X750 |

425 |

50-100 |

40-110 |

55 |

12000 |

|

PE600X900 |

500 |

65-160 |

50-180 |

75 |

17000 |

|

PE750X1060 |

630 |

80-140 |

110-320 |

90 |

31000 |

|

PE900X1200 |

750 |

95-165 |

220-450 |

160 |

52000 |

|

PE300X1300 |

250 |

20-90 |

16-105 |

55 |

15600 |

Production advantages

1)High crushing ratio. Large stones can be quickly broken into small pieces.

2)Hopper mouth adjustment range is large, can meet the requirements of different users.

3)High capacity. It can handle 16 to 60 tons of material per hour.

4)Uniform size simple and Simple maintenance.

5)Simple structure, reliable operation, low operating costs.

6)Low noise, little dust.

Work site

Package and delivery

Spare parts